Kukidhi mahitaji yanayokua kwa kasi ya biochar ya premium katika soko la EU, Watayarishaji lazima wajenge mfumo ambao hutoa ubora thabiti, granules zenye nguvu, na utendaji wa kaboni tayari wa CDR. Kwa hivyo, kuchagua teknolojia ya pyrolysis sahihi, vitengo vya usindikaji wa baada ya, na vifaa vya granulation inakuwa muhimu. Na mstari ulioundwa vizuri, Unaweza kufikia kaboni ya juu, majivu ya chini, na muundo wa sare wakati pia hutengeneza bidhaa zilizoongezwa kwa thamani na mbolea ya msingi wa biochar. Njia hii iliyojumuishwa inasaidia kilimo, kilimo kikaboni, na fursa za kuondolewa kwa kaboni kwa muda mrefu.

Je! Ni suluhisho gani za msingi kwa uzalishaji wa biochar?

Kutengeneza biochar ya hali ya juu kwa kilimo cha EU na mipango ya CDR inahitaji mfumo kamili ambao unajumuisha mstari wa kuaminika wa pyrolysis, Mchakato mzuri wa granulation, na uundaji wa juu wa mbolea ya msingi wa biochar. Kila hatua inachukua jukumu muhimu katika kuamua ubora wa mwisho wa bidhaa, Thamani ya soko, na utayari wa udhibitisho.

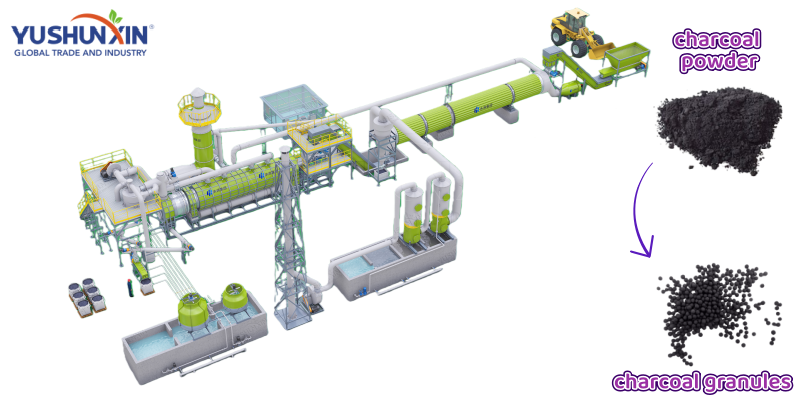

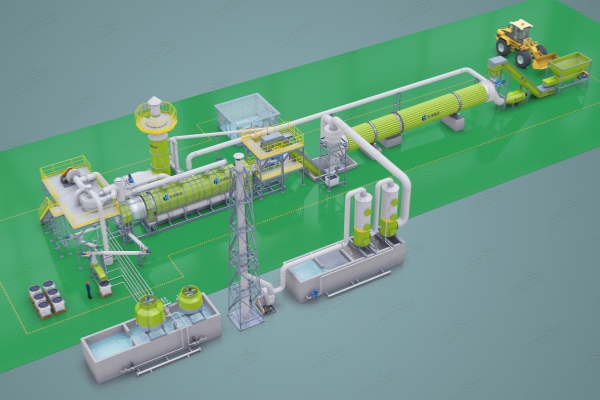

Mstari wa pyrolysis kwa biochar - muundo thabiti na majivu ya chini

Ikiwa lengo lako ni kutengeneza biochar ya daraja la kwanza na kaboni kubwa iliyowekwa, Yaliyomo ya majivu ya chini, na ubora wa chembe, Mfumo wa juu wa pyrolysis unaoendelea ndio suluhisho bora. Wakati wa kuendelea kwa pyrolysis, Biomass inawashwa chini ya joto linalodhibitiwa kwa usahihi na nyakati za makazi, Kuhakikisha kaboni ya sare. Hii husababisha biochar na muundo thabiti, Kupunguza uchafu, na utendaji mzuri kwa uboreshaji wa mchanga. Mstari kamili ni pamoja na kulisha, Reactor ya pyrolysis, baridi, kutoa, na matibabu ya matibabu. Mifumo kama hiyo ni bora kwa masoko ya kilimo ya EU, kilimo kikaboni, kilimo cha maua, na uzalishaji unaostahiki wa CDR kwa sababu hutoa thabiti, Ubora unaoweza kufikiwa.

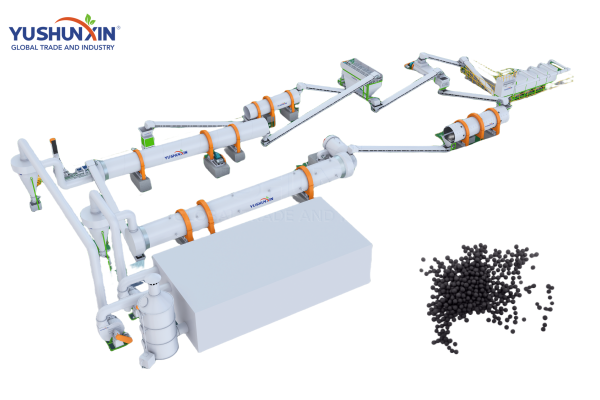

Mstari wa granulation ya Biochar - Nguvu & Pellets za sare

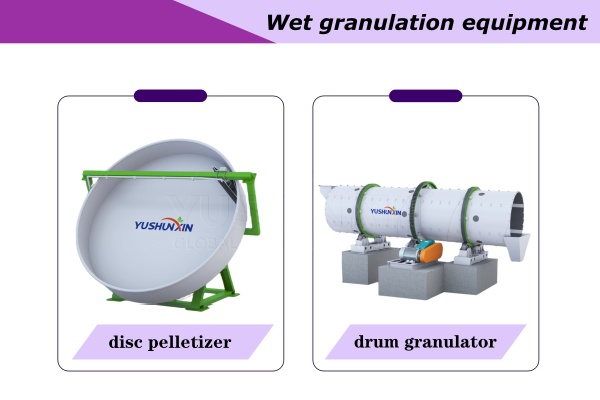

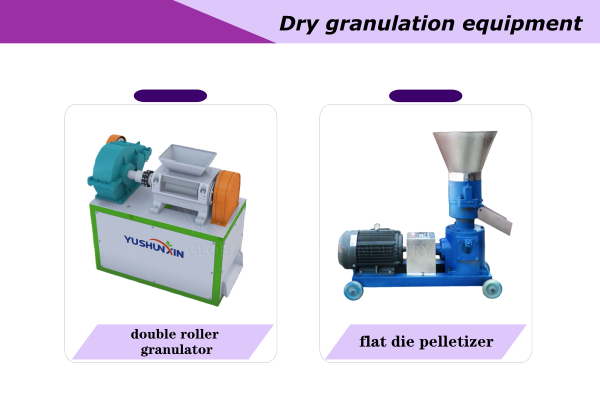

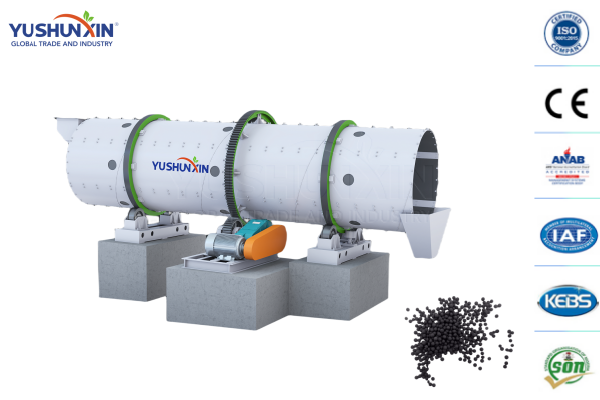

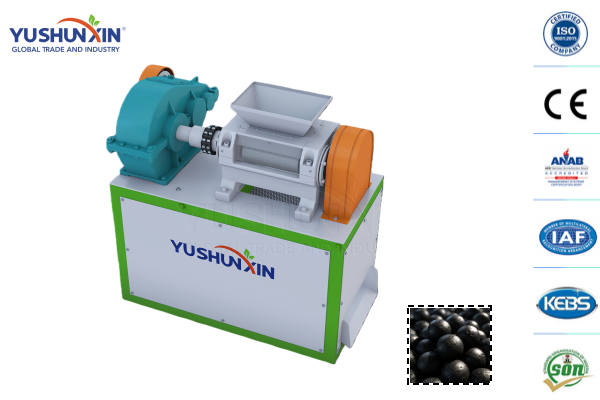

Wakati unataka kubadilisha poda ya biochar huru kuwa bidhaa zenye thamani kubwa, Mchakato wa granulation ni muhimu. Granulation huunda biochar kuwa pellets pande zote na nguvu bora, umoja, na matumizi rahisi katika vifaa vya kilimo. Chini ya nguvu ya mzunguko au ya ziada, Vifaa vya biochar vilivyosindika hutengeneza granules zenye kudumu na za kudumu na mtiririko bora na utulivu wa uhifadhi. Aina hii ya pellet ya premium inapendelea kilimo cha chafu, mizabibu, mazao ya beri, na uboreshaji wa ardhi yenye thamani kubwa. Kwa hatua ya granulation, Pelletizer ya disc au granulators za rotary ngoma ni chaguzi za kawaida kulingana na unyevu, Uundaji, na mahitaji ya uwezo.

Mbinu za mbolea ya msingi wa Biochar-Thamani ya juu na ujumuishaji wa CDR

Ikiwa unazingatia kuongeza utendaji wa bidhaa na thamani ya soko, Kuunda mchanganyiko wa mbolea ya msingi wa biochar ni chaguo bora. Njia hizi zinachanganya biochar na mbolea, madini (CA, Mg, Na), au viongezeo vya kikaboni ili kuongeza utunzaji wa virutubishi, shughuli za microbial, na muundo wa mchanga. Vifaa vilivyochanganywa vinasindika kupitia mchanganyiko na granulation ya hiari kuunda mbolea ya kwanza iliyoundwa kwa matunda, mizabibu, mboga, na mazao ya chafu. Kwa sababu Biochar hufanya kama kuzama kwa kaboni kwa muda mrefu, Bidhaa hizi zinaweza pia kuhitimu udhibitisho wa CDR chini ya viwango kama EBC-CDR na puro.Earth. Njia hii iliyojumuishwa hutoa mito ya mapato mawili: Uuzaji wa mbolea na kizazi cha mkopo cha kaboni kutoka 1 Tani ya biochar inayolingana na tani 2.0-2.4 za CO₂ zilizoondolewa.

Je! Mstari gani wa pyrolysis unafaa kwa uzalishaji wa hali ya juu wa biochar?

Kutengeneza biochar inahitaji mfumo wa pyrolysis ambao hutoa kaboni thabiti, pato thabiti, na ubora wa kuaminika kwa kilimo cha EU na mipango ya CDR. Kwa hivyo, Chagua mstari unaoendelea wa pyrolysis na udhibiti sahihi wa joto na usindikaji mzuri wa baada ya kuwa muhimu. Mchanganyiko huu inahakikisha kaboni ya juu, Yaliyomo ya majivu ya chini, na muundo wa chembe ya sare, ambayo ni muhimu kwa udhibitisho na granulation ya chini. Mfumo ulioundwa vizuri pia unasaidia utulivu wa muda mrefu wa kufanya kazi na kuongeza uhifadhi wa kaboni.

Je! Ni aina gani za mpango wa biashara wa mkaa unaweza kuanza?

Starting a charcoal-making business gives you diverse options because different biomass materials can be carbonized into high-value charcoal products. Below are four profitable charcoal production lines you can consider.

Je! Mifumo tofauti ya granulation huunda vipi pellets zenye nguvu na zenye usawa?

Producing biochar pellets requires choosing the right granulation system based on material moisture, production scale, and target applications. Wet granulation and dry granulation each offer unique advantages, and understanding their differences helps you build a stable, high-output production line. When matched with proper moisture control, Kuchanganya, and screening, both systems can create durable, uniform pellets suitable for EU agriculture, soil improvement, and downstream fertilizer blending.

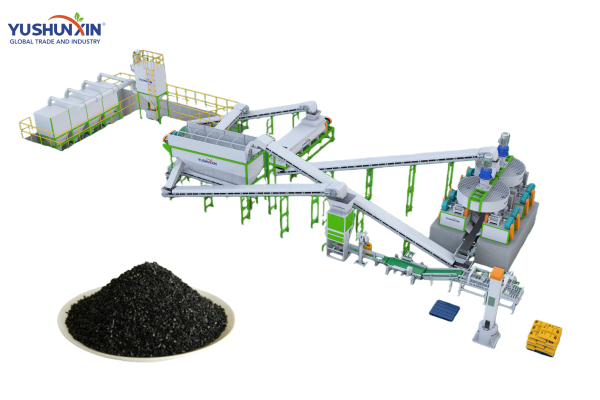

Jinsi ya kutengeneza mbolea ya msingi wa biochar?

Biochar-based fertilizers offer a high-value opportunity for producers who want to serve EU organic farming, greenhouse cultivation, and specialty crop markets. By combining biochar with nutrients, compost, or organic additives, manufacturers can create powerful soil improvers that enhance nutrient retention, boost microbial activity, and support long-term carbon sequestration. With a well-designed production process, these blends achieve stable quality, strong granule strength, and consistent nutrient delivery for berries, mizabibu, mboga, and high-performance greenhouse crops.

Aina za mbolea ya msingi wa biochar

Producers can develop several high-value biochar fertilizer formulations depending on crop needs and soil conditions. Biochar + compost blends improve microbial activity and organic matter levels, making them ideal for horticulture and vegetable production. Biochar + madini (CA, Mg, Na) strengthens soil structure and enhances plant resistance to stress, commonly used in vineyards and berry crops. Biochar with organic additives allows customized nutrient profiles for greenhouse agriculture and specialty crops. Each blend leverages biochar’s high porosity to enhance nutrient retention and long-term soil conditioning.

Mchakato wa uzalishaji wa mbolea ya msingi wa Biochar

When you plan to produce carbon-based fertilizer, it is essential to understand the core processes involved in biochar fertilizer manufacturing. Generally, when you use biochar and compost as raw materials, the production process includes three major steps:

Kuponda biochar na mbolea ndani ya poda nzuri

To produce high-quality biochar fertilizer, you must first crush charcoal blocks, biochar chips, and compost clumps into fine powder. Finer particle size improves the nutrient absorption of powdery fertilizers and enhances pellet formation for granular products. A vertical fertilizer crusher is suitable for handling both biochar and compost, ensuring uniform particle size and preparing materials for efficient mixing and granulation.

Kuchanganya biochar na mbolea sawasawa kwa usawa wa virutubishi

Next, to achieve consistent nutrient distribution in the final fertilizer, the mixed materials must be blended thoroughly. A fertilizer mixer ensures even combination of biochar powder with compost. Depending on your capacity and efficiency needs, you can choose from several mixers, including large-scale horizontal mixers, high-speed double-shaft blenders, or low-cost disc mixers. These systems ensure uniformity and stability for both small-scale and industrial productions.

Kubadilisha mchanganyiko wa biochar -pamoja kuwa granules za mbolea ya kikaboni

If you want to improve storage stability, transport efficiency, and controlled-release performance, granulating the biochar–compost mixture is a highly effective step. You can choose a pan pelletizer for small-scale biochar fertilizer production, a rotary drum granulator for large-scale carbon-based fertilizer manufacturing, or a double roller granulator for low-cost dry granulation without adding water. Each machine helps you produce strong, uniform organic fertilizer granules with higher commercial value.

Biochar + Cdr: Mfano wa mapato mawili kwa miradi ya juu ya ROI

High-quality biochar stores carbon in a stable form for hundreds of years, and therefore becomes one of the most reliable carbon-removal solutions for agriculture and climate markets. Because each ton of biochar permanently removes 2.0–2.4 tons of CO₂, scaling production allows investors to generate both climate impact and stable commercial value. This long-term carbon stability also makes biochar eligible for the most recognized CDR certification systems worldwide.

When your biochar meets EBC-CDR, Puro.Earth, or ICROA-aligned methodologies, it qualifies for high-value carbon credit issuance. These certification systems verify carbon permanence, production process quality, and sustainable sourcing. Kama matokeo, certified producers can access premium markets where carbon credits trade at €200–€400 per ton of CO₂, which significantly increases project profitability and ensures predictable returns.

By combining a continuous pyrolysis line with controlled post-processing and granulation, producers maximize carbon retention and achieve consistent, certifiable product quality. This integration enables dual revenue streams: biochar sales for agriculture and carbon credit sales for CDR programs. Because every certified ton of biochar can generate €400–€960 in carbon credit income alone, investors benefit from accelerated ROI and long-term financial stability.

Makadirio ya mapato ya CDR kwa uzalishaji wa biochar

| Uwezo | Biochar Output (t/day) | CO₂ Removal (t/day) | Carbon Credit Price (€/ tCO₂) | Daily CDR Revenue (€) | Annual CDR Revenue (300 days) |

| 500 kilo/h | 12 t/day | 24–28.8 t/day | €200–€400 | €4,800–€11,520 | €1.44M–€3.45M / mwaka |

| 1000 kilo/h | 24 t/day | 48–57.6 t/day | €200–€400 | €9,600–€23,040 | €2.88M–€6.91M / mwaka |

Notes:

- Calculation based on: 1 ton biochar = 2.0–2.4 tons CO₂ removed

- Revenue only includes carbon credits; biochar sales are additional income

- Annual revenue calculated for 300 operating days

If you have any other want to know about biochar production solution for CDR integration, welcome to contact us now. Kwa kuongeza, Kuna pia bamboo charcoal making plan, wood pellet machine, rice husk pellet making solution, etc here for your choice.