To meet the fast-growing demand for premium biochar in the EU market, producers must build a system that delivers stable quality, strong granules, and CDR-ready carbon performance. Buna görə, selecting the right pyrolysis technology, post-processing units, and granulation equipment becomes essential. With a well-designed line, you can achieve high fixed carbon, low ash, and uniform structure while also creating value-added granulated products and biochar-based fertilizers. This integrated approach supports agriculture, organic farming, and long-term carbon removal opportunities.

What Are the Core Solutions for Biochar Production?

Producing high-quality biochar for EU agriculture and CDR programs requires a complete system that includes a reliable pyrolysis line, an efficient granulation process, and advanced biochar-based fertilizer formulations. Each step plays a critical role in determining the final product quality, market value, and certification readiness.

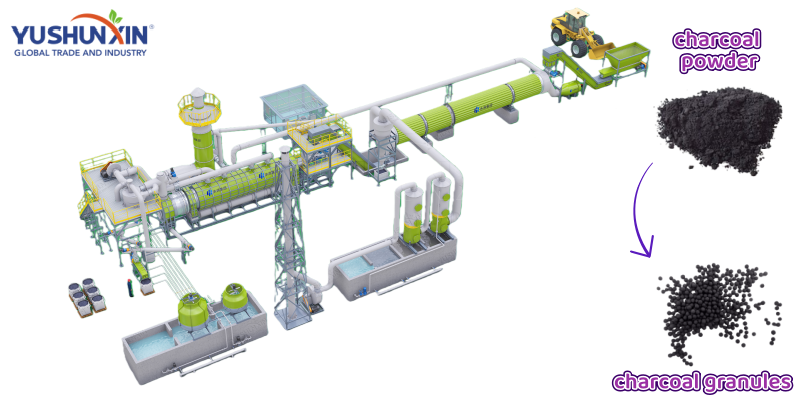

Pyrolysis Line for Biochar – Stable Structure and Low Ash

If your goal is to manufacture premium-grade biochar with high fixed carbon, low ash content, and homogeneous particle quality, an advanced continuous pyrolysis system is the best solution. During continuous pyrolysis, biomass is heated under precisely controlled temperatures and residence times, ensuring uniform carbonization. This results in biochar with stable structure, reduced impurities, and strong performance for soil improvement. A complete line includes feeding, pyrolysis reactor, cooling, discharging, and emissions treatment. Such systems are ideal for EU agricultural markets, organic farming, horticulture, and CDR-eligible production because they deliver consistent, certifiable quality.

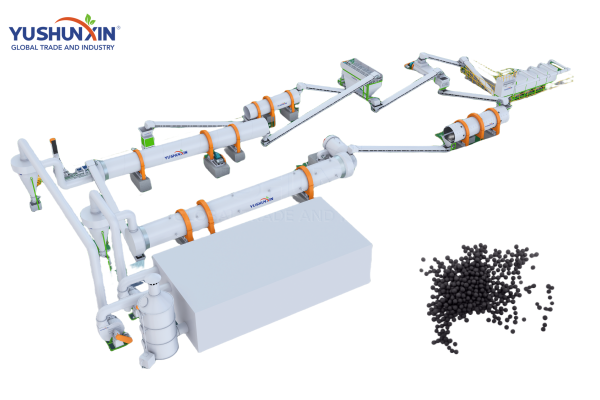

Biochar Granulation Line – Strong & Uniform Pellets

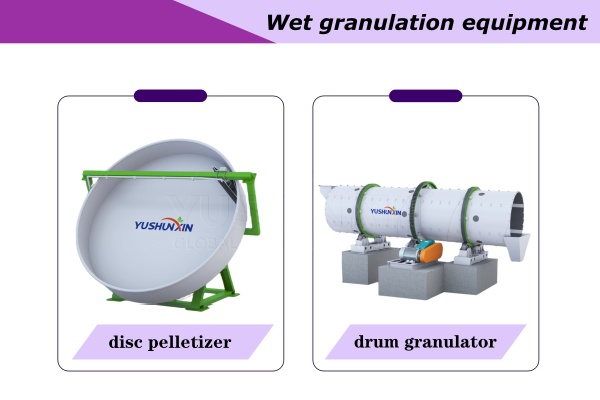

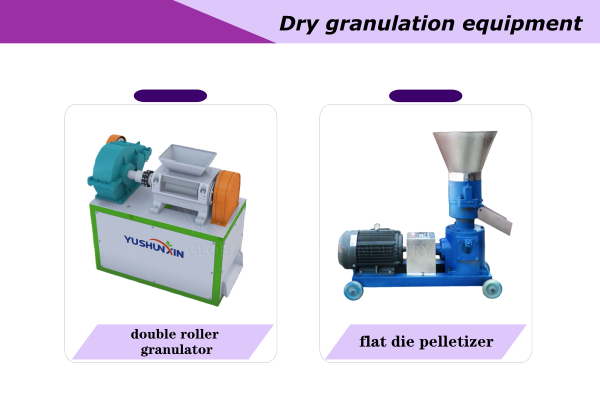

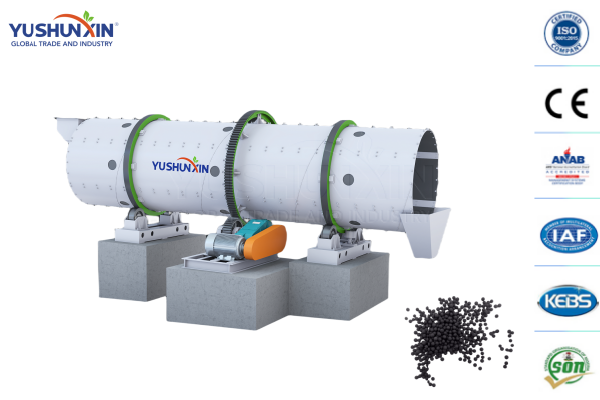

When you want to convert loose biochar powder into higher-value products, the granulation process is essential. Granulation forms the biochar into round pellets with excellent strength, uniformity, and easy application in agricultural equipment. Under rotational or extrusion force, the processed biochar material forms dense and durable granules with improved flowability and storage stability. This type of premium pellet is preferred for greenhouse agriculture, vineyards, berry crops, and high-value soil improvers. For the granulation step, disc pelletizers or rotary drum granulators are common options depending on moisture, formulation, and capacity requirements.

Biochar-Based Fertilizer Formulations – Higher Value and CDR Integration

If you focus on maximizing product performance and market value, creating biochar-based fertilizer blends is an excellent choice. These formulations combine biochar with compost, minerals (Ca, Mg, Si), or organic additives to enhance nutrient retention, microbial activity, and soil structure. The blended material is processed through mixing and optional granulation to create premium fertilizers tailored for berries, vineyards, vegetables, and greenhouse crops. Because biochar acts as a long-term carbon sink, these products can also qualify for CDR certification under standards such as EBC-CDR and Puro.Earth. This integrated approach offers dual revenue streams: fertilizer sales and carbon credit generation from 1 ton of biochar equaling 2.0–2.4 tons of CO₂ removed.

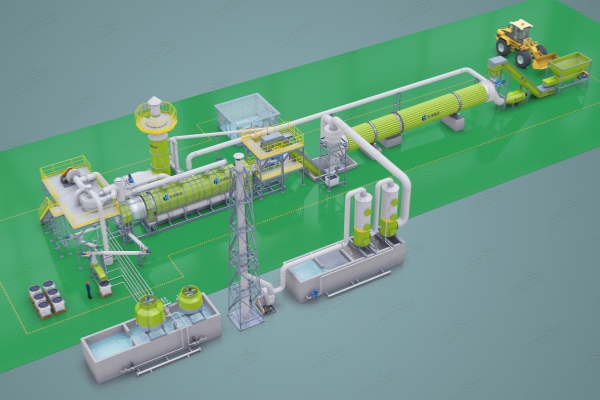

What Pyrolysis Line is Suitable for High Quality Biochar Production?

Producing biochar requires a pyrolysis system that delivers consistent carbonization, stable output, and reliable quality for EU agriculture and CDR programs. Buna görə, choosing a continuous pyrolysis line with precise temperature control and efficient post-processing becomes crucial. This combination ensures high fixed carbon, low ash content, and uniform particle structure, which are essential for certification and downstream granulation. A well-designed system also supports long-term operational stability and maximizes carbon retention.

What Types of Charcoal Making Business Plan you Can Start?

Starting a charcoal-making business gives you diverse options because different biomass materials can be carbonized into high-value charcoal products. Below are four profitable charcoal production lines you can consider.

How Do Different Granulation Systems Create Strong and Uniform Biochar Pellets?

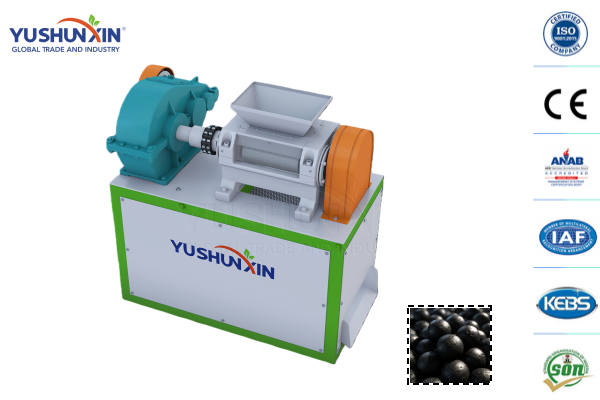

Producing biochar pellets requires choosing the right granulation system based on material moisture, production scale, and target applications. Wet granulation and dry granulation each offer unique advantages, and understanding their differences helps you build a stable, high-output production line. When matched with proper moisture control, mixing, and screening, both systems can create durable, uniform pellets suitable for EU agriculture, soil improvement, and downstream fertilizer blending.

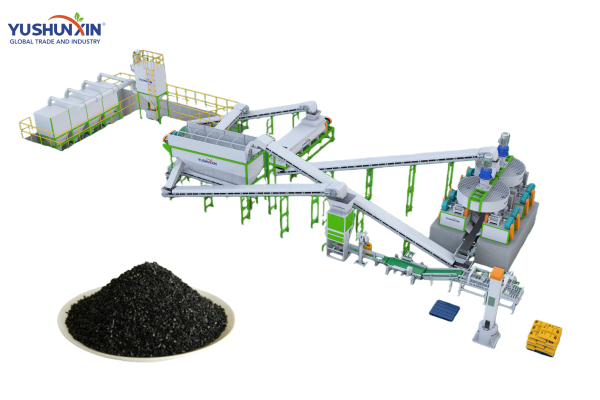

How to Make Biochar-Based Fertilizer?

Biochar-based fertilizers offer a high-value opportunity for producers who want to serve EU organic farming, greenhouse cultivation, and specialty crop markets. By combining biochar with nutrients, compost, or organic additives, manufacturers can create powerful soil improvers that enhance nutrient retention, boost microbial activity, and support long-term carbon sequestration. With a well-designed production process, these blends achieve stable quality, strong granule strength, and consistent nutrient delivery for berries, vineyards, vegetables, and high-performance greenhouse crops.

Types of Biochar-Based Fertilizers

Producers can develop several high-value biochar fertilizer formulations depending on crop needs and soil conditions. Biochar + compost blends improve microbial activity and organic matter levels, making them ideal for horticulture and vegetable production. Biochar + minerals (Ca, Mg, Si) strengthens soil structure and enhances plant resistance to stress, commonly used in vineyards and berry crops. Biochar with organic additives allows customized nutrient profiles for greenhouse agriculture and specialty crops. Each blend leverages biochar’s high porosity to enhance nutrient retention and long-term soil conditioning.

Biochar-Based Fertilizer Production Process

When you plan to produce carbon-based fertilizer, it is essential to understand the core processes involved in biochar fertilizer manufacturing. Generally, when you use biochar and compost as raw materials, the production process includes three major steps:

Crushing Biochar and Compost into Fine Powder

To produce high-quality biochar fertilizer, you must first crush charcoal blocks, biochar chips, and compost clumps into fine powder. Finer particle size improves the nutrient absorption of powdery fertilizers and enhances pellet formation for granular products. A vertical fertilizer crusher is suitable for handling both biochar and compost, ensuring uniform particle size and preparing materials for efficient mixing and granulation.

Mixing Biochar and Compost Evenly for Nutrient Balance

Next, to achieve consistent nutrient distribution in the final fertilizer, the mixed materials must be blended thoroughly. A fertilizer mixer ensures even combination of biochar powder with compost. Depending on your capacity and efficiency needs, you can choose from several mixers, including large-scale horizontal mixers, high-speed double-shaft blenders, or low-cost disc mixers. These systems ensure uniformity and stability for both small-scale and industrial productions.

Turning the Biochar–Compost Blend into Organic Fertilizer Granules

If you want to improve storage stability, transport efficiency, and controlled-release performance, granulating the biochar–compost mixture is a highly effective step. You can choose a pan pelletizer for small-scale biochar fertilizer production, a rotary drum granulator for large-scale carbon-based fertilizer manufacturing, or a double roller granulator for low-cost dry granulation without adding water. Each machine helps you produce strong, uniform organic fertilizer granules with higher commercial value.

Biochar + CDR: A Dual-Revenue Model for High ROI Projects

High-quality biochar stores carbon in a stable form for hundreds of years, and therefore becomes one of the most reliable carbon-removal solutions for agriculture and climate markets. Because each ton of biochar permanently removes 2.0–2.4 tons of CO₂, scaling production allows investors to generate both climate impact and stable commercial value. This long-term carbon stability also makes biochar eligible for the most recognized CDR certification systems worldwide.

When your biochar meets EBC-CDR, Puro.Earth, or ICROA-aligned methodologies, it qualifies for high-value carbon credit issuance. These certification systems verify carbon permanence, production process quality, and sustainable sourcing. As a result, certified producers can access premium markets where carbon credits trade at €200–€400 per ton of CO₂, which significantly increases project profitability and ensures predictable returns.

By combining a continuous pyrolysis line with controlled post-processing and granulation, producers maximize carbon retention and achieve consistent, certifiable product quality. This integration enables dual revenue streams: biochar sales for agriculture and carbon credit sales for CDR programs. Because every certified ton of biochar can generate €400–€960 in carbon credit income alone, investors benefit from accelerated ROI and long-term financial stability.

CDR Revenue Estimation for Biochar Production

| Güc | Biochar Output (t/day) | CO₂ Removal (t/day) | Carbon Credit Price (€/ tCO₂) | Daily CDR Revenue (€) | Annual CDR Revenue (300 days) |

| 500 kg/h | 12 t/day | 24–28.8 t/day | €200–€400 | €4,800–€11,520 | €1.44M–€3.45M / il |

| 1000 kg/h | 24 t/day | 48–57.6 t/day | €200–€400 | €9,600–€23,040 | €2.88M–€6.91M / il |

Notes:

- Calculation based on: 1 ton biochar = 2.0–2.4 tons CO₂ removed

- Revenue only includes carbon credits; biochar sales are additional income

- Annual revenue calculated for 300 operating days

If you have any other want to know about biochar production solution for CDR integration, welcome to contact us now. Üstəlik, there are also bamboo charcoal making plan, wood pellet machine, rice husk pellet making solution, etc here for your choice.